WE BUILD

A COOL WORLD

INNOVATION

IN REFRIGERATION

NEVER COMPROMISE

ON QUALITY

WE ACCOMPANY

CUSTOMERS' BUSINESS GROWTH

COOLPLUS Commercial Refrigeration China, as a pioneer walk-in cold room manufacturer and supplier, supplies the whole range of cold storage refrigeration units including cold room condensing units of walk-in cooler condenser unit and walk-in freezer condenser unit, and cold room evaporator coils of walk-in cooler evaporator unit cooler and walk-in freezer evaporator unit cooler for different chilling or freezing storage temperature of walk-in cold storage rooms and refrigerated warehouses.

Professional commercial walk-in cold room manufacturer and export supplier in China specializing in commercial & industrial cold storage warehouse design and construction with nearly 30 years of experience in commercial refrigeration and cold storage industry. Superior Quality, and Affordable Price.

Prefabricated Cold Room : Modular Walk-in Cooler Cold Store

Prefabricated Modular Walk-in Cooler Cold Store is a walk-in cooler room with prefabricated cold room panel, pre-installed condenser unit and evaporator unit so that the cold store can be easily and simply installed within a short time at the installation location. This walk-in refrigerator is typically a cold store for refrigerated foods storage, and usually with small capacity besing used at places like restaurant, supermarket, hotel, convenient store, butcher's shop, hospital, pharmacy etc.

This prefab commercial walk in cooler cost is lower. The mudlar walk in cooler prices range from US$3000 ~ US$10000. It's a small investing cold storage which is suitable for small retail business.

These small size walk in cooler cold rooms are with the volume of less that 100 cubic meters. This small cold store basically consist of three parts: Walk in Cooler Panels, Walk in Cooler Door, and Walk in Cooler Refrigeration Units.

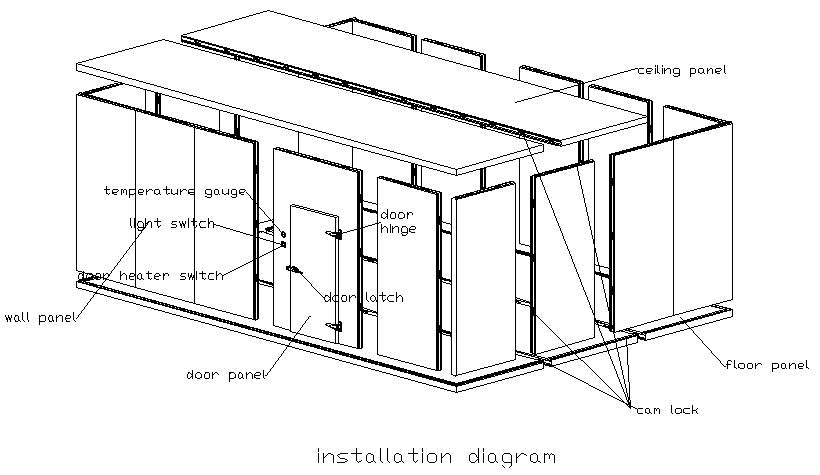

This type of small cold storage rooms are a modular cold room, which is made of Prefabricated Polyrurathane (PU) Insulated Sandwich Panel with cam lock design. Our factory prefabricate all the insulation panels including wall panel, ceiling panel and floor panel during production exactly according to the cold room desgin diagram to ensure the walk-in cooler panels can connect perfectly at the exact positions. While the cold storage insulation boards for large walk in refrigerated warehouses may need cutting at the cold storage warehouse installation site when doing the cold room construction to adjust panel connection.

These prefabricatedly designed cold room panels will be shipped in unassembled knock-down form. After you receive the shipment, you can connect the cold storage room panels according to the provided design diagram with a small hex key simply and conveniently We will mark serial numbers on all panels corresponding to the design diagram to help you make the cold room panel installation just so simple and easy.

The refrigeration system of the Walk-in Cool Room Outdoor Condensing Unit and Indoor Evaporating Unit will also be shipped by pre-installed finished way. The condenser unit is a hermetic box type refrigeraion unit with powerful fan motor and evaporater unit a split type indoor unit. Only copper pipe connection work will be done at the installation site. The modular cold room refrigeration system installation is also easy and simple.

Comparing to Modular Walk-in Chiller Room (at the chilling temperature of -5 ~ 10 ℃) for fresh storage and Walk-in Freezer Room (at the freezing temperature of -10 ~ -30 ℃) for frozen storage, this Walk-in Cooler Room is for longer term of cooling storage at the refrigerated storage temperature of -5 ~ 20 ℃.

Walk in Cooler Condenser Unit

Walk in Cooler Evaporator Unit

This small modular walk-in cooler cold store is with the features of fast cooling, energy saving, full automatic operation, safe and stable operation, and low cost. They are widely used in retail sales industry and other foodservice places with small refrigeration capacity requirement.

| Model | Descriptions | Storage Volume | Storage Temp. | Exterior Dimension (mm) | Interior Dimension (mm) | Condenser / Power | Evaporator / Power | Condenser Dimn.(mm)/NW | Evaporator Dimn.(mm)/NW | Liquid Line/Suction Line | Voltage |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WR-10 | 8'x8' Walk-in Cooler/Chiller | 10 m3 | > -5℃ | 2366W x 2366L x 2300H | 2166W x 2166L x 2100H | DC-20FHG / 1900W | DL15/180W | 840W x 310L x 700H / 50kg | 1130W x 425L x 465H / 30kg | 10mm / 16mm | 220V/50Hz |

| WR-15 | 8'x12' Walk-in Cooler/Chiller | 15 m3 | > -5℃ | 2366W x 3549L x 2300H | 2166W x 3349L x 2100H | DC-20FHG / 1900W | DL15/180W | 840W x 310L x 700H / 50kg | 1130W x 425L x 465H / 30kg | 10mm / 16mm | 220V/50Hz |

| WR-20 | 8'x16' Walk-in Cooler/Chiller | 20 m3 | > -5℃ | 2366W x 4732L x 2300H | 2166W x 4532L x 2100H | DC-20FHG / 1900W | DL15/180W | 840W x 310L x 700H / 50kg | 1130W x 425L x 465H / 30kg | 10mm / 16mm | 380V/50Hz 3P |

| WR-23 | 12'x12' Walk-in Cooler/Chiller | 23 m3 | > -5℃ | 3549W x 3549L x 2300H | 3349W x 3349L x 2100H | DC-20FHG / 1900W | DL15/180W | 840W x 310L x 700H / 50kg | 1130W x 425L x 465H / 30kg | 10mm / 16mm | 380V/50Hz 3P |

| WR-26 | 8'x19' Walk-in Cooler/Chiller | 26 m3 | > -5℃ | 2366W x 5915L x 2300H | 2166W x 5715L x 2100H | DC-30FHG / 2650W | DL30/270W | 920W x 320L x 850H / 53kg | 1580W x 425L x 465H / 49kg | 10mm / 16mm | 380V/50Hz 3P |

| WR-30 | 12'x16' Walk-in Cooler/Chiller | 30 m3 | > -5℃ | 3549W x 4732L x 2300H | 3349W x 4532L x 2100H | DC-30FHG / 2650W | DL30/270W | 920W x 320L x 850H / 53kg | 1580W x 425L x 465H / 49kg | 10mm / 16mm | 380V/50Hz 3P |

| WR-40 | 12'x19' Walk-in Cooler/Chiller | 40 m3 | > -5℃ | 3549W x 5915L x 2300H | 3349W x 5715L x 2100H | DC-30FHG / 2650W | DL30/270W | 920W x 320L x 850H / 53kg | 1580W x 425L x 465H / 49kg | 10mm / 16mm | 380V/50Hz 3P |

| WR-43 | 16'x16' Walk-in Cooler/Chiller | 43 m3 | > -5℃ | 4732W x 4732L x 2300H | 4532W x 4532L x 2100H | DC-40FHG / 3800W | DL30/270W | 920W x 320L x 850H / 53kg | 1580W x 425L x 465H / 49kg | 10mm / 16mm | 380V/50Hz 3P |

| WR-54 | 16'x19' Walk-in Cooler/Chiller | 54 m3 | > -5℃ | 4732W x 5915L x 2300H | 4532W x 5715L x 2100H | DC-50FHG / 4850W | DL40/500W | 940W x 340L x 1240H / 110kg | 1330W x 605L x 630H / 68kg | 12mm / 19mm | 380V/50Hz 3P |

| WR-68 | 19'x19' Walk-in Cooler/Chiller | 68 m3 | > -5℃ | 5915W x 5915L x 2300H | 571W x 5715L x 2100H | DC-80FHG / 7500W | DL80/1100W | (920W x 320L x 850H / 53kg)x 2 | (1580W x 425L x 465H / 49kg) x 2 | (10mm / 16mm) x 2 | 380V/50Hz 3P |

Remarks:

1. Walk-in Cooler Size and Storage Temperature can be customized.

2. Standard Voltage: 380V ±10%, 50Hz, 3Ph or 220V ±10%, 50Hz, 1Ph. 110V/60Hz, 220V/60Hz and 380V/60Hz availability to be confirmed.

3. 220V ±10%, 50Hz, 1Ph: China, Vietname, Cambodia, Thailand, Malaysia, Indonesia, Australia, New Zealand, Bangladesh, India, Sri Lanka, Pakistan, Afghanistan, Uzbekistan, Turkmenistan, Kazakhstan, Georgia, Azerbaijan, Iran, Iraq, UAE, Yemen, Turkey, Egypt, Ethiopia, Kenya, Tanzania, Mozambique, Madagascar, South Africa, Angola, Congo, Cameron, Nigeria, Ghana, Cote d'Ivoire, Morocco, Algeria, Libya, Tunisia, Italy, Greece, Spain, Portugal, Britain, France, Germany, Sweden, Norway, Finland, Poland, Hungary, Ukraine, Serbia, Croatia, Romania, Bulgaria, Russia, Chile, Argentina, Paraguay etc.

220V ±10%, 60Hz, 1Ph: Korea, Saudi Arabia, Philippines, Peru etc.

110V ±10%, 60Hz, 1Ph: Japan, United States, Canada, Mexico, Ecuador, Brazil, Colombia, Venezuela etc.

Besides the standard modular walk in coolers with specific room size and storage temperature, we also provide customized cold room design services and manufacture walk in cooler cold rooms as per our customers' Customized Cold Room Dimensions and Desired Storage Temperatures.

We also manufacture prefabricated walk in coolers made of cold room sandwich panels with different metal skins of Pre-Coated Galvanized Mild Steel, Embossed Aluminum, and 304 Stainless Steel to meet different foods sanitary requirements, different ambient temperature and humidity requirements as per our different customers' requirements. For the storage of foods with packages, the galvanized mild steel cladding sandwich panel may meet the requirment in consideration of cost-efficiency. While in case of tropical areas and sea side areas with high temperature and high humidity, aluminum cladding sandwich panels may be required to ensure the anti-corrosion of the insulated panels. And in some pharmaceutical and lab projects, we may need stainless steel cladding walk in cooler panels to meet the high sanitory standard.

Contact us now for more technical and specification details.

Customers shall choose cold room specification and types of cold storage warehouses according to stored goods, storage temperature, storage volume, land and building conditions etc. Welcome to send enquiry for cold room design and construction, cost and price and cold room panel supply.