WE BUILD

A COOL WORLD

INNOVATION

IN REFRIGERATION

NEVER COMPROMISE

ON QUALITY

WE ACCOMPANY

CUSTOMERS' BUSINESS GROWTH

COOLPLUS Commercial Refrigeration China, as a pioneer Cold Room Panel manufacturer and cold storage warehouse supplier, manufactures and supplies a whole range of cold storage panels of both walk-in cooler panel and walk-in freezer panel to build commercial cold storage rooms and industrial refrigerated warehouses. Our prefabricated cold room Sandwich Panels include PUR Insulated Panel (Polyurethane Foamed Insulation Panel), PIR Insulated Panel (Polyisocyanurate Foamed Insulation Panel) and XPS Insulated Panel (Extruded Polystyrene Foamed Insulation Panel) with galvanized mild steel surface skin, aluminum surface skin or stainless steel surface skin for wall paenl, ceiling panel and floor panel. PUR insulated sandwich panel with cam lock design is suitable to be used for smaller size mudlar walk-in cooler and modular walk-in freezer cold storage rooms. PIR insulated sandwich panel is suitable to be used for large size industrial refrigerated warehouse facility. And XPS insulated panel with strong anti-stress is suitable to be used as cold storage floor insulation panel.

Our cold room panels are the Fireproof Cold Storage Boards tested by Fire Resistance Class B1 (Nonflammable) with the features of No Melt Dropping, Self-Extinguishing, and Flame Spread Resistance. The cold room baords are with High Thermal Efficiency with the thermal conductivity low to 0.0214 W/(m·k) The Polyurethane Foam (PU Foam) density of our cold room sandwich slab is 40±2kg/m3 which is strictly according to the JB/T 6527-2006 Standard - The Sandwich Panel Used for Prefab Cold Store.

Professional cold room panel supplier in China specializing in industrial & commercial walk-in cold room design and construction with nearly 30 years of experience in commercial refrigeration and cold storage industry. We have exported our insulated sandwich cold room panels to countries like the United States, Canada, South Amercia, Australia, Europe, Indonesia, Malaysia, Vietname, Sri Lanka, India, Bangladesh, Pakistan, Middle East, South Africa, Madagascar, Tanzania, Mozambique, Kenya, Ethiopia, Egypt, Tunisia, Libya, Morocco, Ghana, Congo, Cameron, Angola, Nigeria etc. with our superior cold storage panel quality and ompetitive cold room panel price.

Walk-in Cold Room Panel is a prefabricated composite sandwich panel with two higher-strength metal surfaces and a lighter and lower-strength injecting insulated core material is foamed between the metal skin. This prefabricated insulated panel is one of the key components of a cold storage room, it directly determines the thermal insulation efficiency and energy cost, cold room structure stability and service lifespan.

According to the foamed insulated materials, there are six types of sandwich panels: polystyrene foamed sandwich panel(EPS sandwich board), extruded polystyrene foamed sandwich panel(XPS sandwich board), rigid polyurethane foamed sandwich panel(PU sandwich board), polyisocyanurate foamed sandwich panel(PIR sandwich board), phenolic foamed sandwich panel(PF sandwich board), rock wool foamed sandwich panel(RW sandwich board). Based on the product performance and technical characteristics of the insulated slabs, our factory has manufactured 3 types of insulated foamed sandwich panels as cold room panel:

Cold Room Panels should have 4 important characteristics: excellent thermal insulation, perfect sealing, strong anti-compression and anti-bending, and strong frost resistance.

Our cold room panels are available with both Rigid Injected Polyurethane Foam (PUF) and Polyisocyanurate Foam (PIR). The most ideal thermal insulation materials for cold room building are PUR (PUF) and PIR. We have used both PUR Sandwich Panel and PIR Sandwich Panel as cold room Wall Panel and Ceiling Panel.

Polyisocyanurate Insulated Panel(PIR Panel), as a new type of thermal insulation panel, makes an excellent perfmance in cold room insulation.

Polyisocyanurate Foam, also known as "polyisocyanuric acid" or "PIR", is a kind of plastic composed of closed cell foam which is made from isocyanate and polyether after the reaction with catalytic agent. The physical characteristics and fire resistance of PIR are better than those of polyurethane(PUR). It is an ideal low temperature thermal insulation material with low thermal conductivity, light weight and strong adaptability. It is widely used in LNG, natural gas, refinery, petrochemical plant, liquid nitrogen, liquid oxygen ethylene, fertilizer, cold storage and construction industry.

Cost-Effective Cold Storage Panel Solution : Our factory adopts computer-controlled fully-automatic production line to manufacture this PIR Cold Storage Board. With the continous production line without the need of much labour force, we dramatically reduce the production cost of manufacturing this cold room panel, and thus offer our cold storage customers very competitive price cold room panels. And with the precise computer-control design and setting of production parameters, we also supply refrigerated warehouse users high quality cold storage boards .

Why it matters: Less heat exchange through the panel means better insulation efficiency and means less energy cost for the cold room.

How our cold room panels perform: The K-factor thermal conductivity of our PUR foamed polyurethane sandwich panel is from 0.022 to 0.026 W/mK (at 25 ℃). And the thermal conductivity of PIR foamed polyisocyanurate sandwich panel can be as low as 0.018 W/mK (at 25 ℃) which ensures high insulation performance, low energy-consumption, and great cost saving on electricty bill during cold room operation.

Why it matters: Cold room safety is the vital matter in cold storage contruction. Any safety problem might cause huge loss of products stored in, loss of cold storage facility, and loss of life. In the old days, amonia refrigeration system is one of the key cause of safety problem. Nowdays, the key safety factor of cold room construction is cold room panels. It is very important to choose the right cold room panels.

On September 16, 2022 PM 03:48, there was an outbreak of fire on Changsha China Telecom Building. The fire extinguished at PM 04:20. Within less than 1 hour, the insulated layer of the exterior side of the building wall of the 218-meter tall skyscraper was totally burned and destroyed. The cause of the fire is under investigation, but apparently the insulated material for the exterior wall was not the fireproof type, and it caused the disaster. Fire Resistance should be the vital concern on choosing the insulated panel for our cold storage warehouse building.

What's Behind the 39 Death?

According to the investigation report released on Sep. 21, 2024 by experts in construction, fire protection, cold storage and static electricity, the investigation team found that the direct cause of the accident was the illegal construction of cold storage on the basement floor of the building. When the polyurethane foam caulk was used in the construction operation, the release of flammable gas reaches the flammable conditions. The electrostatic discharge ignited the accumulated flammable gas when laying plastic film on the extruded plastic board. And it then quickly ignited flammable and combustible materials such as polyurethane foam board and extruded plastic board, and produced a large amount of toxic smoke which caused the disaster.

To prevent the like disasters, check the below for our Safe and Fireproof Cold Storage Boards.

How COOLPLUS cold room panels perform on Fire Resistance

The standard fire resistance of PUR foam panel is generally Class B3, by adding flame retardants, it can reach Class B2. The addition of fire retardant materials to insulated slab does not make an item non-combustible, but slow fire down, have a lower flame spread and reduce fire risk.

The fire resistance of PIR foam panel is generally B2 grade, by adjusting the concentration of polyisocyanuric acid ring and other formula technology, it can reach Class B1 level, and the oxygen index can reach more than 35%.

Both the PUR Sandwich Panel and PIR Sandwich Panel manufactured by our factory are Fire Resistance Class B1 Flame Retardant Material according to the Fire Retardant Standard of GB8624-1997 "Classification for Burning Behavior of Building Materials and Products" which is equivalent to low flammability of EN 13501-1 European Fire Classification of Construction Products and Building Elements, and is effective against fire exposure, and can be used safely in a commercial environment and ensure cold storage facillity safety and reliability.

COOLPLUS B1 Class (Nonflammable) Fire Resistant PIR Polyurethane Insulated Cold Storage Boad Fire Burning & Flame Spread Resistance Tests

★No Melt Dropping ★ Self Extinguishing ★ Flame Spread Resistance ★

Sample Description: Polyisocyanurate (PIR) Core Material (1500X1000) mmX4PC+(1500X495) mmX4PC

| Inspection Item | Measurement & Unit | Technical Requirements B1(C) Level |

Inspection Data | Single-Item Evaluation |

|---|---|---|---|---|

| Fire Growth Rate (Combustion Performance) |

FIGRA0.4MJ (W/s) | ≦250 | 130 | PASS |

| Lateral Flame Spread (Combustion Performance) |

LFS (m) | The lateral flame spread does not reach the long wing edge of the test sample | The lateral flame spread does not reach the long wing edge of the test sample | PASS |

| Total Heat Release (Combustion Performance) |

THR600s (M/J) | ≦15 | 5 | PASS |

| Flammability | mm | Combustible flame tip height Fs ≦ 150mm in 60s | 58 | PASS |

| / | No phenomenon of burning droplets igniting filter paper in 60s | No burning droplets | PASS | |

| Oxygen Index | OI (%) | ≧30 | 33.5 | PASS |

Inspection Basis:

Inspection Items: Fire Growth Rate, Lateral Flame Spread, Total Heat Release, Flammability, and Oxygen Index.

Inspection Conclusion: After inspection, the tested items meet the requirements of above listed standards. The test data can be found in the above inspection results (attached table).

Our polyisocyanurate insulated panel is a new revolutionary fire resistant PIR insulation board that has the feature of Self Extinguishing & Flame Spread Resistance Function which no melt droppings occur in case of fire and fire burning of the insulation slab stops immediately when fire is moved away. This will effectively stop the fire spreading. PUF sandwich panel is suitable for small cold store like walk-in cooler and walk-in freezer. However, for large cold store warehouse which has very critical requirement on fire resistance, we strongly recommend our PIR foamed sandwich panel which meets the requirements of GB8624 Fire Resistance-Rated Class B1 (Nonflammable) and has higher flame retardancy.

PUR insulated panel is usually used below 110 ℃, while the temperature range for PIR insulated panel is -196℃ ~ +150℃.

PIR Panel has the characteristics of good dimensional stability, strong compression resistance and low thermal conductivity when used in ultra-low temperature environment.

The density of polyurethane panel is generally in the range of 35 ~ 45 kg/m3 which provides satisfactory strength requirements. But PIR panel requires the density of 45 to 55 kg/m3 in order to achieve the satisfactory strength requirements.

The water absorption rate for PUR cold room panel is generally from 2.5% to 3%. And the water absorption rate for our PIR insulated cold room panel is as low as up to 0.9% which is much less.

Thermal insulation performance of the insulated panels will decrease sharply under the condition of water absorption, at the same time dimensional stability will decrease sharply too and causes panel warp distortion leading to the panel cracking and cooling air leakage. So our cold room panels should have low water absorption rate.

Polyisocyanurate Foam Insulated Sandwich Panel is a new type of cold room panel. Few cold room panel producers are qualified to produce this insulation panel. As a cold room panel manufacturer in China with nearly 30 years of manufacturing experience of different types of insulated boards, our factory has been able to supply PIR insulated Sandwich Panel to our customers for the excellent cold room insulation and saving electricity consumption and cold room operation cost.

Sample Description: 50cmX50cmX5cm yellow-white foam 4 pieces in good condition with packing

| Inspection Item | Unit | Inspection Data | Single-Item Evaluation |

|---|---|---|---|

| Density | kg/m3 | 41.4 | PASS |

| Compressive Strength | kPa | 178 | PASS |

| Thermal Conductivity (average temp. 23℃) |

W/(m·k) | 0.0214 | PASS |

| Water Absorbtion Rate | % | 1.9 | PASS |

| Length Stability (80℃,48h) |

% | 0.9 | PASS |

| Width Stability (80℃,48h) |

% | 0.8 | PASS |

| Thickness Stability (80℃,48h) |

% | 0.9 | PASS |

Inspection Basis:

Inspection Items: Density, Compressive Strength, Thermal Conductivity, Water Absorbtion Rate, Length Stability, Width Stability, and Thickness Stability.

Inspection Conclusion: After inspection, the tested items meet the requirements of above listed standards. The test data can be found in the above inspection results (attached table).

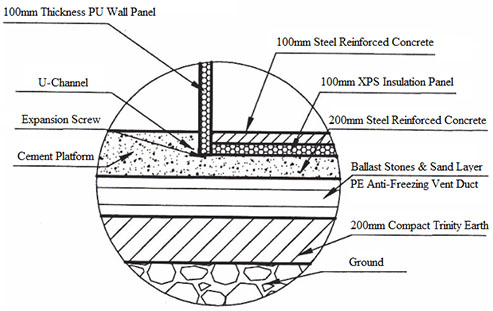

Extruded Polystyrene Foam Panel is a rigid foam board made of polystyrene resin and other raw materials and polymers. XPS foam panel has a perfect closed cell honeycomb structure, which makes the XPS board have very low water absorbency (almost no water absorption), low thermal conductivity, high compressive resistance, and aging resistance.

XPS panel is usually used as cold room floor insulation panel with SBS vapour barrier at the bottom and top of the slab.

XPS insulated panel has the characteristics of high thermal resistance, low linearity and low expansion ratio. The closed cell ratio of the XPS panel reaches more than 99%, forming a vacuum layer, avoiding air flow and heat dissipation, and ensuring the lasting and stable thermal insulation performance. Its thermal conductivity is much lower than that of EPS panel with the same thickness. Practice has proved that the insulation effect of 20 mm XPS extruded insulation board is equivalent to that of 50 mm thick EPS board. Therefore, this material is the ideal choice for cold storage thermal insulation.

Cold storage warehouse floor panel needs to bear the stack a lot of goods and heavy loading and unloading machinery and equipment, so its structure should be solid and have a large bearing capacity.

Due to the special structure of XPS board, its compressive strength reaches 150-500kpa or more. It is widely used in Geothermal Engineering, expressway, airport runway, square ground, large size refrigerated warehouse and vehicle interior decoration and insulation. The excellent structural bearing effect makes XPS insulated slab a perfect choice for large refrigerated warehouse floor insulation.

Because the molecular structure of XPS panel is not water absorbing, the foam panel is stable and there is no gap. Water repellent and moisture-Proof mean high frost resistance and the panel will work well at extreme low temperature. It avoids the problems of water leakage, moisture penetration, frosting and condensation leading to the thermal insulation decrease at low temperature. This moisture-proof characteristic makes XPS insulated panel perfect for large cold room floor insulation.

Easy to cut, transport and install, not easy to damage.

In the long-term use, XPS foam insulated panel does not age, decompose or produce harmful substances. Its chemical properties are extremely stable, and it does not degrade due to water absorption and corrosion. XPS slab can still maintain its superior performance in high temperature environment. According to practice, extruded polystyrene insulated panel can maintain excellent performance for 30-40 years, and does not decompose or mildew, and there is no toxic volatilization.

The characteristic of high strength of XPS plate makes the plate brittle and not easy to bend. When the plate is stressed, the stress concentration is easy to make the plate damaged and cracked.

Therefore, by considering the pros and cons of XPS plate, we only use XPS insulated board as cold room floor panel with concrete layer above for protection instead of using it as wall panel to avoid the disadvantage of being easily-cracked and take the advantage of excellent thermal insulation.

XPS foam board is almost airtight, if the temperature difference on both sides of the board is large, high humidity is easy to condense.

The smooth surface makes XPS panel not firmly bonded, easy to fall off from other substances.Therefore, it is not suitable to be used as cold room wall panels. And we use XPS insulation panel as Cold Storage Floor Insulation Boards.

As a cold storage warehouse manufacturer and designer with nearly 30 years of building experience, it is our honor to make suitable proposals to our customers for right cold room panels and cold storage warehouse design and construction.

Polyurethane(PU or PUR) is a kind of polymer product by the reaction of polyisocyanate and polyether or polyester polyol in a certain proportion. The main materials for polyurethane are MDI, TDI and PPG.

Polyurethane has 3 forms: rigid polyurethane foam, soft polyurethane foam and elastic polyurethane. Rigid polyurethane foam plastic is with the characteristics of light, sound insulation, thermal insulation, chemical resistance, good electrical properties, easy processing, and low water absorption.

Rigid polyurethane insulation board is widely used in large industrial plants, cold stores, refrigerator and freezer insulation, garages, mobile houses, exhibition halls, gymnasiums, shopping centers, airports, power plants, villas, hospitals, strata and high-rise office buildings. Due to its excellent thermal insulation performance, it is mainly used in the roof and wall of cold storage warehouse, industrial and civil buildings.

Sample Description: Double-Cladding PPGI Polyurethane Cold Room Panel 1500X1000x150(mm)X3PC+1500X500x150(mm)X3PC+500X500x150(mm)X2PC

| Inspection Item | Measurement & Unit | Judgment Criteria & Technical Requirements | Actual Testing Result | Single-Item Evaluation |

|---|---|---|---|---|

| Fire Growth Rate (Combustion Performance) |

FIGRA0.2MJ (W/s/5.1.1) | ≦120 | 33.2 | PASS |

| Total Heat Release (Combustion Performance) |

THR600s (M/J/5.1.1) | ≦7.5 | 2.5 | PASS |

| Lateral Flame Spread (Combustion Performance) |

LFS (m/5.1.1) | < edge of the test sample | In conformance | PASS |

| Combustible Flame Tip Height Fs in 60s | (mm/5.1.1) | ≦ 150mm | 51 | PASS |

| Is filter paper ignited? | 5.1.1 | Filter paper is not ignited | In conformance | PASS |

| Smoke Growth Rate (Smoke Properties) |

SMOGRA (m²/s²/5.1.1) | s1≦30 s2≦180 s3 falls short of s2 |

48.6 |

PASS (Level s2) |

| Total Smoke Production (Smoke Properties) |

TSP600s (m²/5.1.1) | s1≦50 s2≦200 s3 falls short of s2 |

198.6 |

PASS (Level s2) |

| Burning Droplets/Granules | 5.1.1 | No burning droplets/granules in 600s | In conformance | PASS |

Inspection Basis:

Inspection Items: Fire Growth Rate, Total Heat Release, Lateral Flame Spread, Combustible Flame Tip Height, filter Paper Ignition, Smoke Growth Rate, Total Smoke Production, and Burning Droplets.

Inspection Conclusion: After inspection, the tested items meet the requirements of above listed standards. The test data can be found in the above inspection results (attached table).

The PUF sandwich panel has low thermal conductivity and good thermal performance. When the density of rigid polyurethane is 35 ~ 43 kg/m3, the thermal conductivity is only 0.018 ~ 0.024 W/mK, which is about half of EPS panel, which is among the lowest of all thermal insulation materials.

The rigid polyurethane insulated panel has a closed cell rate above 90%. This kind of hydrophobic material will not increase the thermal conductivity due to moisture absorption, and the wall made of this PU panel will not seep.

The PUF panel is a flammable self extinguishing material after adding flame retardants. Its softening point can reach above 250 ℃. In addition, polyurethane will form carbon deposits on its foam surface when burning, which helps to isolate the foam under it. This can effectively prevent the spread of flame. Moreover, polyurethane does not produce harmful gas at high temperature.

During combusion by fire, a carbonization is formed on the surface of the insulation board. No Continuous Flame lasts. No Burning Droplets fall down on the floor. These characteristics of our cold storage panels significantly prevent fire increading and stop flame spread, and tremendously ensure the safety of cold storage warehouse construction and cold room use.

Compressing strength: 200 KPa. Bending strength: 331 KPa. Not easy to crack, stable and safe.

The closed cell structure of the polyurethane foam panel not only provides good thermal insulation performance, but also has good freeze-thaw resistance and sound absorption. The average service life of PU insulated sandwich panel can reach more than 30 years under normal use conditions.

Although the unit price of PUR sandwich panel is higher than that of other traditional insulation panels, the increased cost will be offset by a substantial reduction in the energy cost brought by the excellent thermal insulation efficiency of the polyurethane insulated panel, and so makes it cost-effective.

Sample Description: Polyurethane Sandwich Panel 2400mmX250mmX100mm)X3PC

| Inspection Item | Unit | Nameplate Parameter | Technical Requirements Specified in the Standard | Inspection Data | Single-Item Evaluation |

|---|---|---|---|---|---|

| Density | kg/m3 | 40 | 40±2 | 40.03 | PASS |

| Compressive Strength | kPa | / | ≧160 | 171 | |

| Thermal Conductivity | W/(m·k) | / | ≦0.024 | 0.021 | PASS |

| Bonding Strength | MPa | / | >0.100 | 0.152 | PASS |

| Flexural Bearing Capacity | mm | / | ≦8.80 | 4.55 | PASS |

| Length Stability | mm | 2400 | ±2 | 1.0 | PASS |

| Width Stability | mm | 250 | 0~-3 | -0.7 | PASS |

| Thickness Stability | mm | 100 | ±1 | 0.2 | PASS |

| Dimensional Deviation | mm | / | ±3 | 2 | PASS |

Inspection Basis: JB/T 6527-2006 The Sandwich Panel Used for Prefab Cold Store

Inspection Items: Density, Compressive Strength, Thermal Conductivity, Bonding Strength, Flexural Bearing Capacity, Dimensional Deviation, and Appearance Quality.

Inspection Conclusion: After inspection, the tested items meet the requirements of JB/T 6527-2006 standard. The test data can be found in the above inspection results (attached table).

1st Generation Cold Room Insulation Panel - EPS Panel (Expanded Polystyrene Insulated Board)

2nd Generation Cold Room Insulation Panel - PUR Panel (Polyurethane Insulated Board)

3rd Generation Cold Room Insulation Panel - PIR Panel (Polyisocyanurate Insulated Board)

PIR Panel(Polyisocyanurate Panel) is made by the reaction of polyether polyols or polyester polyols and isocyanates. Under the action of trimerization catalyst, the excess isocyanate reaction generates a six-membered ring, which provides crosslinking to the foam, and at the same time promotes the combustion and coking of the carbon through its six membered-ring molecular structure to prevent flame from burning. PIR Slab has good flame penetration and low smoke emission during combustion, and improves the fire resistance of the foam system. The fireproof performance can reach panel core material Grade B1 .

As stipulated in GB50072 Code for Design of Cold Store, when a cold storage warehouse adopts metal surface insulation sandwich plate as thermal insulation enclosure, the combustion performance of the filling material shall not be lower than Grade B1. To meet the requirements of this Chinese national standard, the best thermal insulation material is PIR. PIR is an ideal organic thermal insulation material with low thermal conductivity, The operating temperature range is wide (ranging from - 200 ℃ ~ + 150 ℃). As a new international cold insulation material, PIR Board has been used in petrochemical energy engineering, construction, environmental protection and energy conservation, cold chain insulation and other fields.

| Panel Type | Density (kg/m3) | Thermal Conductivity (W/m.k) | Water Absorbtion Rate (%) | Combustion Performance |

|---|---|---|---|---|

| PUR Panel | 35~50 | ≤0.024 | <2% | Flame Retardant B2 |

| PIR Panel | 35~50 | ≤0.021 | <1% | Flame Retardant B1 |

| EPS Panel | 18~22 | 0.041 | <3% | Flame Retardant B2 |

| XPS Panel | 25~35 | 0.035 | <2% | Flame Retardant B2 |

| Rockwool Panel | 80~150 | 0.057 | <3% | Incombustible A1 |

Remarks:

- The foaming density is an important factor affecting the quality of cold storage board. The lower density, the better insulation. The higher density, the higher compressing strength. The panel density needs to be at the balance.

- The lower panel thermal conductivity means the better insulation efficiency.

- The lower water absorbtion rate the better to prevent moisture penetration into panel core foam causing insulation efficiency reduction and panel embrittlement.

Thermosetting thermal insulation materials such as polyurethane rigid foam are superior to thermoplastic thermal insulation materials such as EPS in structural fire prevention. Polyurethane Foam (PU and PIR) will not melt and drip in case of fire and can maintain the stability of the structure.

Our insulation panel factory has introduced a full set of continuous PIR cold room board production line, adopted with advanced technology from Europe. And through the localized practice for more than 20 years, our shear emulsification technology and pure plate foaming technology of foaming machine have surpassed those of Europe. We have accumulated rich rigid foam insulation manufacturing experience and highly specialized application technology in the past years, and it ensures the high quality and reliability of our cold storage panel products.

Our cold room panel production lines adopt multi-component foaming machine system. At present, the world's advanced PIR production technology is to apply the high-pressure continuous foaming technology of no less than 5 components, that is, the online adjustment of catalyst, foaming agent, flame retardant, pol and ISO. At present, most Chinese production line foaming machine systems are still 2-component or 4-component foaming machines with limited adjustment parameters, and so the guarantee of quality index and physicochemical performance is limited.

We select five components that can be dynamically adjusted online to adapt to various changes in temperature difference, reaction time, flow, pressure, density, flame retardant characteristics and black-and-white material index. The automatic tracking conditions ensure uniform material distribution and reaction matching, so as to ensure a series of quality indexes such as foaming density, dimensional stability, flame retardant effect and uniform strength. We make the breakthrough on the technical difficulties of large-scale production of PIR rigid foam polyurethane continuous plate production line. It is a great significance for the promotion of Chinese energy-saving, thermal insulation and fireproof materials and the realization of PIR insulation panel as popular construction material.

MATERIAL COST MATTERS, OPERATION COST MATTERS MORE.

| Standard Panels | Our Cold Room Panels | Benefit to Customers | |

|---|---|---|---|

| Thermal Conductivity (W/m.k) | 0.024 | 0.019 | Save 20% operating costs |

| Combustion Performance | B2 Flame Retardant or None | B1 Flame Retardant | Safer. 100% pass on extinguishing and protection tests |

| Quality Control | PPGI from small factories | PPGI from brand manufacturers | Durable service life, and less maintenance cost |

| Production Time | Small production capacity | Large production capacity with manufacuring flexibility | Fast delivery, and short warehouse construction cycle |

Our cold room panels are in conformity with the following Chinese executive standards, and some European and American equivalent standard tests have been done.

COOLPLUS is committed to the research & development and manufacturing of high-quality cold storage insulation panels with best performance.

We manufacture 4 types of cold room panel skin. Cold room owners and contractors may choose according to their use purposes of the walk-in cold rooms for the insulation panel cladding metal sheets.

Pre-Painted Galvanized Iron Sheet(PPGI) Sandwich Panel is the most widely-used wall panel and ceiling panel due to its durable life and low cost. We produce both 0.426mm thickness to 0.8mm thickness PPGI insulated sandwich panels according to the room size requirements.

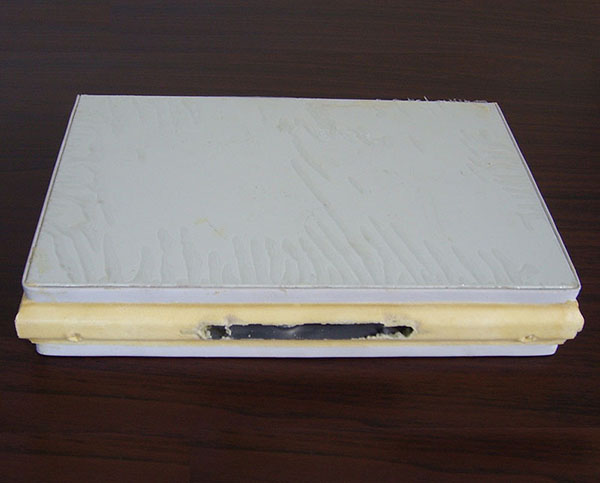

The inside and outside surfaces of the insulated sandwich slab are with plastic laminated hot dipped pre-coated galvanized steel colour bond sheet cladding. Optionally, it is possible to produce one panel side with PPGI and the other panel side with aluminum or stainless steel metal sheets. Special sealing gaskets can be provided on the interior and interim edge of the tongue and groove joint of the insulation slab.

Stainless steel is required in some high standard cold room. We produce the 0.56mm thickness stainless steel sandwich panel. But its cost is relatively higher comparing to PPGI panel and aluminium panel.

The price of Embossed Aluminium Sandwich Panel is between PPGI and stainless steel. We produce 0.426mm thickness aluminium insulated sandwich panel.

The Zinc-Coated Sandwich Panel is mainly used as cold room floor panel. Also we can produce checkered non-slip floor panel when customer requires.

What thickness of cold room panels should I choose for my cold storage rooms and refrigerated warehouses?

Panel Thickness: Our cold room panels are available with 5 types of thickness. Below is the panel thickness corresponding to cold storage temperature:

Length: Upto 13.5 meters according to the height of cold storage warehouse.

Width: The standard width of PU Sandwich Panel is based on the module of 295.3mm, which can be increased to 590.6mm, 885.8mm and 1181.1mm. Customzied panel width is also available.

According to cold room size and panel length, we provide two options for panel locking: cam lock system & tightening system.

For modular cold rooms of walk-in cooler and walk-in freezer, each pair of panels are equipped with a set of eccentric locks with one piece prefabricated in each panel to correspond with each other, and the two panels can be locked together with a small wrench to hook each other.

This easy fast assembly and disassembly type reversible cam locks and tongue and groove panels make it easy to assemble walk-in cold rooms from inside and can move the walk in cold storage rooms to desired places conveniently.

Cold Room Panel Cam Lock system Eccentric Locks

High Quality Metal Cam Lock Instead of Plastic One

Hook Cold Room Boards Firmly

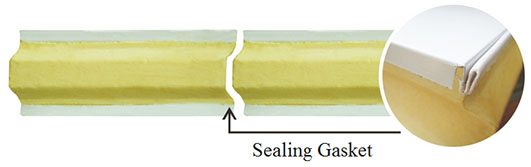

The sandwich panel's edge is with Male-Female Desgin to ensure the perfect panel joining and complete sealing. The interlocking panel design makes it very easy and simple to join cold room panels within a short time and makes cold room installation and assembling an easy job. What's more, the eccentricit cam lock design makes it the same easy to disassemble the walk-in cold room and move to another place for reinstallation at any time you want.

Furthermore, our modular walk-in cold room sandwich panels are equipped with a sealing gasket around the panel edge to seal the panel joining and ensure no moisture can penetrate into the panel and damage the insulation material due to water condensing at low temperature.

For large size cold storage warehouse with tall height requiring long length panel, we use the panels with Tightening Locking System to enforce the joining strength between panels. And usually these large refrigerated warehouses are civil cold rooms which we don't need to move to another place after the installation. So tightening locking system panel design is good to ensure the cold room structure stability.

When we build a large cold storage warehouse, we usually need to make a concrete cold storage floor. In this case, the floor insulation board will be a bare surface XPS board without the metal skins of sandwich panel. In order to prevent moisture and water penetration into the bare surface insulation board, we will need to have a SBS Vapor Barrier Sheet (Styrene-Butadiene-Styrene Rubber Modified Aspha Paper) under and above the insulation board for waterproofing purpose.

When we build walk-in cold rooms like restaurant walk in cooler, supermarket walk in chiller or aquatic product walk in freezer with wet floor environment, we may need an anti-skidding cold storage floor for safety reason. We can make the cold room floor panel with interial metal sheet of slip-resistant checkered stainless steel or non-slip checkered aluminum. This antiskid floor sheet can be prefabricated to the floor sandwich panel during production instead of covering on the floor after the cold room is assembled.

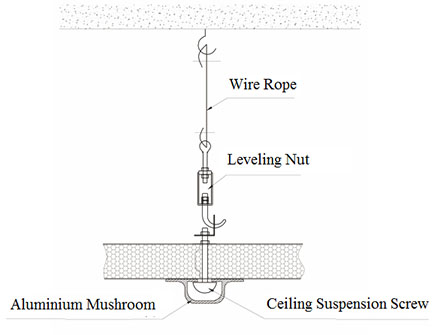

The walk in cold room ceiling panels are suspended to the beams of the warehouse steel structure if we construct a large cold storage warhouse. If we build a small walk-in cooler or walk-in freezer cold stores, then the cold room ceiling suspension is not necessary while the ceiling boards will be laid on one end of the cold store wall slab to the opposite side of the cold store wall slab.

When the walk in cold room celing panels are with long length, we will add auxiliary ceiling suspension to ensure the ceiling panels don't bend down by its own panel weight besides the primary ceiling suspension to fix the panel connection.

As a leading cold room panel manufacturer and supplier in China and the only manufacturing factory with both fully automatic polyisocyanurate foam injection insulated sandwich panel production line and semi automatic pulyurethane foam injection insulated sandwich panel production line, we are looking for cold storage panel distributors in Japan, United States, Canada, Mexico, Ecuador, Brazil, Colombia, Venezuela, Korea, Saudi Arabia, Philippines, Peru, Vietname, Cambodia, Thailand, Malaysia, Indonesia, Australia, New Zealand, Bangladesh, India, Sri Lanka, Pakistan, Afghanistan, Uzbekistan, Turkmenistan, Kazakhstan, Georgia, Azerbaijan, Iran, Iraq, UAE, Yemen, Turkey, Egypt, Ethiopia, Kenya, Tanzania, Mozambique, Madagascar, South Africa, Angola, Congo, Cameron, Nigeria, Ghana, Cote d'Ivoire, Morocco, Algeria, Libya, Tunisia, Italy, Greece, Spain, Portugal, Britain, France, Germany, Sweden, Norway, Finland, Poland, Hungary, Ukraine, Serbia, Croatia, Romania, Bulgaria, Russia, Chile, Argentina, Paraguay etc. And if you are planning to build a cold storage warehouse, please feel free to send us your enquiry with cold storage panel sizes and thicknesses for our cold room panel price quotation.

Customers shall choose cold room specification and types of cold storage warehouses according to stored goods, storage temperature, storage volume, land and building conditions etc. Welcome to send enquiry for cold room design and construction, cost and price and cold room panel supply.